WEST MICHIGAN MACHINE SHOP (NVC2213)

West Michigan Machine Shop

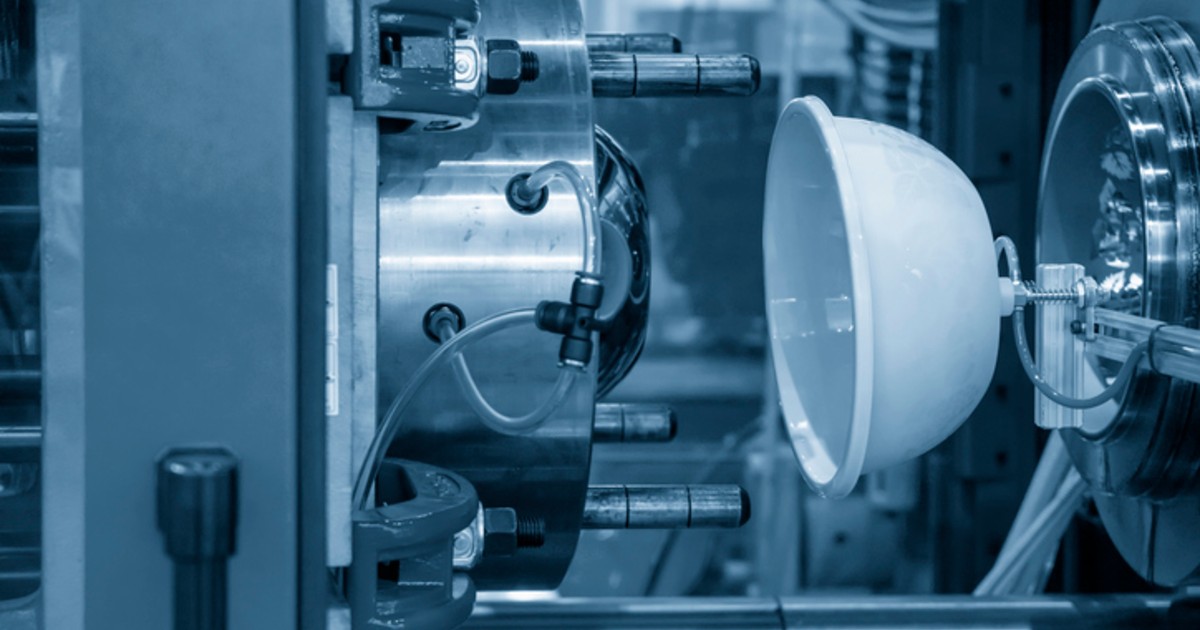

This Company is a full-service, high-quality machine shop that builds a diverse range of precision machined parts. With expertise in CNC milling and lathing, the Company primarily works in the machine building, railroad, and industrial equipment industries, supplying OEM and secondary suppliers. Established in 1965, the Company has a history of years of consistent profitability, and positive cash flow as the owners built the business through an emphasis on quality work and close customer support. The Company also has a small welding department and supplies fabricated assemblies as well. This Company is ready to resume its growth under a new owner who provides machining leadership expertise and brings capital to invest in expanded production capabilities. The business was purchased from the company’s founder in 2002, and the current owner would like to retire.

GROWTH OPPORTUNITIES

Sales Investment to Utilize Capacity – The Company has sufficient space to more than double current

production. An investment in additional capital equipment, along with increasing support staff in product

estimating and sales could build on the Company’s reputation and boost sales to match the Company’s

production capabilities.

Expanded Product Line – A capital investment in new equipment to produce large parts could expand sales

with complementary product to add sales volume with new and existing customers.

INVESTMENT HIGHLIGHTS

Strong Reputation and Customer Relationships – Expertise and efficiency with attractive price points have developed long-term relationships with the Company’s larger customers, and have also led to referrals for new business opportunities.

Quality Staffing – The Company’s top manager and its employees have extensive experience in the industry. Production staff is very experienced, with most of the workforce being with the company in excess of 15 years.

Expertise in Production – As it has grown, the Company has focused on applying newer top-quality, wellmaintained equipment.

Make-to-order Specialty – The Company’s focus on serving customers needing custom parts in small quantities sets it apart.

3-Year Average Revenue: $ 1,400,000

3-Year Average Adjusted EBITDA: $ 150,000

Recent Comments